Palm oil processing, a cornerstone of global food production, involves intricate steps from fruit bunch to refined oil. This complex process, spanning multiple stages from raw material handling to final product refinement, shapes the supply chain and has significant environmental and economic implications. Different methods exist, each with varying degrees of efficiency, cost, and environmental impact, requiring careful consideration for sustainable practices.

The journey begins with receiving and preparing fresh palm fruit bunches, followed by meticulous cleaning and sorting. Extraction techniques, ranging from traditional methods to advanced technologies, determine the oil yield and quality. Subsequent refining and fractionation processes further purify the oil, yielding valuable by-products. Crucially, quality control and adherence to standards are paramount for ensuring consumer safety and product consistency. Environmental considerations and sustainable practices are increasingly important in the industry.

Introduction to Palm Oil Processing

Palm oil, a ubiquitous vegetable oil, plays a crucial role in global food and industrial sectors. Its widespread use in various products, from food to cosmetics, necessitates a sophisticated and extensive processing industry. This intricate process ensures the extraction and refinement of high-quality palm oil, meeting the demands of diverse markets.

The palm oil processing industry is a complex web of activities, from harvesting fresh fruit bunches to refining the final product. Understanding the stages involved in palm oil extraction, the diverse processing methods, and the global significance of this commodity is essential to comprehending its economic and environmental impact.

Stages of Palm Oil Extraction

The journey of palm oil from the fruit to the consumer involves several distinct stages. Harvesting fresh fruit bunches marks the initial step, followed by the meticulous process of separating the fruit from the bunch. The subsequent stage involves extracting the oil from the fruit, typically using mechanical methods like pressing or centrifugation. The extracted crude palm oil is then refined to remove impurities and achieve the desired quality standards.

Types of Palm Oil Processing Methods

Several methods exist for extracting and refining palm oil, each with its own characteristics and implications. Common methods include mechanical pressing, solvent extraction, and a combination of both. The choice of method depends on various factors, including the scale of production, the desired quality of the final product, and economic considerations.

Global Significance of Palm Oil Processing

Palm oil’s global significance is undeniable. It serves as a vital ingredient in countless products, including food items, personal care products, and industrial applications. This substantial demand necessitates a robust and efficient processing industry, directly impacting the economies of producing nations and indirectly influencing global markets.

Comparison of Palm Oil Processing Methods

| Method | Efficiency | Cost | Environmental Impact |

|---|---|---|---|

| Mechanical Pressing | Generally lower efficiency compared to solvent extraction, but more environmentally friendly. | Lower initial capital investment, but higher operating costs due to potential for higher labor needs and lower yield per input. | Lower environmental impact due to lower energy consumption and less reliance on chemical solvents. However, land use and deforestation can be significant concerns. |

| Solvent Extraction | Higher efficiency in extracting oil, potentially leading to higher yield per input. | Higher initial capital investment in specialized equipment, but potentially lower operating costs due to higher efficiency. Solvent disposal is a significant cost factor. | Higher environmental impact due to solvent use, potential for pollution from solvent residue, and increased energy consumption. |

| Combined Method (Pressing & Solvent Extraction) | Can achieve a balance between efficiency and environmental impact, often optimizing oil yield and reducing environmental footprint compared to solvent extraction alone. | Moderate capital investment, with operational costs depending on the specific combination of methods employed. | Moderately lower environmental impact compared to solvent extraction, with a focus on optimizing both oil yield and minimizing environmental harm. Deforestation remains a critical concern in many palm oil regions. |

Raw Material Handling and Preparation

Efficient raw material handling and preparation are critical for maximizing palm oil yield and quality. Proper procedures ensure minimal fruit loss, maintain fruit integrity, and reduce contamination risks throughout the processing chain. This crucial stage directly impacts the overall profitability and sustainability of palm oil production.

Receiving and Preparing Fresh Fruit Bunches

The process begins with the meticulous receipt of fresh fruit bunches (FFBs). Careful inspection for ripeness, damage, and contamination is paramount. Bunches are then sorted by size and quality to optimize processing efficiency. This preliminary sorting also identifies potential issues that can be addressed early on in the process. The goal is to minimize the time the FFBs are exposed to environmental factors like sun or rain, as these can negatively affect the quality and yield of the final product. This step ensures that the fruits are ready for the subsequent processing steps and are in the best possible condition for optimal extraction.

Cleaning and Sorting Techniques

Thorough cleaning and sorting are essential to remove debris, dirt, and unwanted materials from the FFBs. This process typically involves a combination of mechanical and manual methods. Mechanical methods, such as vibrating screens and brushes, are used for initial cleaning, removing large debris. Subsequent manual sorting is used to eliminate small particles, damaged fruits, and any extraneous matter. The selection of cleaning techniques often depends on the specific size and type of the processing facility, as well as the local environmental conditions. Accurate sorting and cleaning contribute to minimizing contamination and maximizing the recovery of high-quality palm fruit for processing.

Transportation and Storage Methods

The method of transporting FFBs significantly impacts the quality of the final product. Direct transportation from the plantation to the mill is often preferred to minimize losses due to spoilage. Modern transport systems like refrigerated trucks or covered vehicles maintain the quality of the fruit bunches. Alternatively, temporary storage facilities with controlled conditions, such as shade-houses or well-ventilated warehouses, can be used to manage the harvest influx and prevent oversaturation of the mill. The choice of transportation and storage methods should align with the geographical location, availability of infrastructure, and the volume of FFBs to be processed.

Flow Chart of Raw Material Handling

[A visual flow chart depicting the entire process, from FFB arrival to processing readiness, would be presented here. The chart should include steps such as receiving, sorting, cleaning, transportation, and storage. It would clearly show the sequential steps and the points of decision-making throughout the process.]

Potential Issues and Solutions for Managing Raw Material Quality

| Issue | Description | Solution |

|---|---|---|

| Fruit Spoilage | Excessive exposure to sun or rain, improper storage, or delayed processing can lead to fruit deterioration, impacting oil extraction and quality. | Employing shaded storage areas, using refrigerated trucks for transportation, and streamlining the processing timeline are crucial. |

| Contamination | Foreign materials like stones, leaves, or other debris in the FFBs can lead to contamination and processing issues. | Implementing effective cleaning and sorting procedures, including both mechanical and manual methods, is essential. |

| Fruit Ripeness Variation | Inconsistencies in fruit ripeness can affect the quality of extracted oil and overall processing efficiency. | Implementing precise ripeness assessment techniques and adjusting processing parameters based on fruit ripeness stages will improve the quality of the final product. |

| High Humidity | High humidity levels can promote the growth of microorganisms and accelerate spoilage. | Implementing proper ventilation systems in storage facilities and ensuring the dryness of the environment during transportation will minimize the risks. |

Oil Extraction Techniques

The processing of palm fruit into palm oil hinges critically on efficient and safe extraction methods. Different techniques yield varying degrees of oil extraction rates, impacting the overall profitability and sustainability of the operation. Understanding these methods and their associated equipment is essential for optimizing palm oil production.

Oil extraction techniques for palm fruit encompass a range of methods, each with its own advantages and disadvantages in terms of cost, efficiency, and environmental impact. The selection of the optimal technique often depends on factors such as the scale of the operation, the quality of the raw material, and the desired level of oil purity.

Mechanical Pressing

Mechanical pressing is a widely used method for extracting oil from palm fruit, particularly in smaller-scale operations. This process involves applying mechanical pressure to the processed palm fruit to force out the oil. The effectiveness of this method depends heavily on the initial preparation and the quality of the pressing equipment.

Solvent Extraction

Solvent extraction, often employed in large-scale operations, utilizes organic solvents to dissolve the oil from the palm fruit. This method typically yields a higher oil extraction rate compared to mechanical pressing, but it carries environmental concerns related to solvent disposal. The choice between mechanical pressing and solvent extraction frequently hinges on economic factors and regulatory standards.

Comparison of Extraction Techniques

| Method | Effectiveness | Efficiency | Environmental Impact | Cost |

|---|---|---|---|---|

| Mechanical Pressing | Moderate | Lower | Lower | Lower |

| Solvent Extraction | High | High | Higher (solvent disposal) | Higher |

The table above provides a comparative overview of the different extraction methods. Solvent extraction, while highly effective and efficient, often comes at a higher cost and carries more environmental concerns associated with solvent disposal. Mechanical pressing, on the other hand, is typically less costly and has a lower environmental impact but yields a lower oil extraction rate.

Equipment for Mechanical Pressing

The equipment used in mechanical pressing varies depending on the scale of the operation. Small-scale operations may utilize simple screw presses, while larger facilities employ hydraulic presses. The screw press mechanism applies pressure gradually, while hydraulic presses exert high pressure rapidly. Proper maintenance and calibration of these machines are crucial for efficient and safe operation. The choice of equipment directly affects the yield and quality of the extracted oil.

Equipment for Solvent Extraction

Solvent extraction utilizes specialized equipment designed for handling solvents and ensuring a controlled environment. This includes solvent tanks, extraction vessels, and separation equipment. The solvent extraction process requires careful monitoring and control to ensure the safety of personnel and the environment. Sophisticated systems for solvent recovery and recycling are often integrated to minimize environmental impact.

Safety Procedures

Safety procedures are paramount in all palm oil processing stages, including oil extraction. Adequate ventilation, personal protective equipment (PPE), and emergency response protocols are crucial. Handling of solvents necessitates stringent safety precautions, including specialized storage, handling procedures, and emergency spill response protocols. The potential hazards associated with each method dictate the specific safety protocols required.

Equipment Specifications

| Method | Equipment | Specifications |

|---|---|---|

| Mechanical Pressing | Screw Press | Capacity: 1-10 tons/hour; Pressure: 10-50 bar; Dimensions: 2-5 m length |

| Mechanical Pressing | Hydraulic Press | Capacity: 10-100 tons/hour; Pressure: 50-200 bar; Dimensions: 5-10 m length |

| Solvent Extraction | Extraction Vessel | Capacity: 100-1000 liters; Pressure: 0.5-5 bar; Temperature: 20-60°C |

| Solvent Extraction | Solvent Tanks | Capacity: 1000-10000 liters; Pressure: 0.5-5 bar; Temperature: 20-60°C |

Refining and Fractionation

Palm oil, after extraction, undergoes refining to enhance its quality and safety for various applications. This crucial step removes impurities, undesirable components, and free fatty acids, leading to a more stable and palatable product. Fractionation further refines the oil, separating it into different fractions based on their properties, creating a range of products tailored to specific needs.

Refining processes are critical to the quality and safety of palm oil, ensuring its suitability for human consumption and industrial applications. The removal of impurities, particularly free fatty acids, prevents rancidity and improves the oil’s shelf life. This is essential for manufacturers of food products, cosmetics, and biodiesel, all of which rely on the stability and purity of the refined oil.

Steps in Refining Palm Oil

The refining process typically involves several steps designed to remove impurities and improve the oil’s characteristics. These steps include degumming, neutralization, bleaching, and deodorization. Each step targets specific contaminants and improves the overall quality of the oil.

- Degumming: This initial step removes gums and mucilage, which are natural components found in the raw palm fruit. These substances can affect the oil’s stability and clarity. Degums are often removed through a chemical process utilizing specific agents that selectively precipitate the unwanted substances. This process ensures a cleaner and more homogenous oil.

- Neutralization: This stage removes free fatty acids (FFAs), which contribute to rancidity and negatively impact the oil’s flavor and stability. Alkaline agents are employed to neutralize these FFAs, resulting in a more stable and palatable product. The neutralization process is critical for preventing unwanted odors and off-flavors.

- Bleaching: Bleaching is performed to remove pigments and colorants from the oil, producing a more uniform and appealing product. Activated carbon or other bleaching agents are utilized to absorb these impurities. The color of the refined oil is a key indicator of the quality and effectiveness of the bleaching process.

- Deodorization: This final step involves removing volatile compounds and undesirable odors from the oil. The oil is heated under vacuum, and the volatile compounds are removed, leading to a product with a pleasant aroma and taste. This process ensures the final product has a desirable flavor profile, crucial for consumer acceptance.

Methods of Refining Palm Oil

Different refining methods exist, each with varying degrees of effectiveness and cost.

- Solvent Extraction: A common method that involves using solvents to extract the oil from the palm fruit. Solvent refining methods often yield a high-quality product, but the use of solvents raises environmental concerns regarding disposal and potential health risks.

- Mechanical Refining: This method relies on mechanical processes to separate impurities, and it is less costly than solvent extraction. However, the quality of the final product may vary depending on the specific mechanical techniques used.

Importance of Refining in Palm Oil

Refining is essential for producing a safe and high-quality palm oil product. The removal of impurities, such as free fatty acids and gums, improves the stability, color, and flavor of the oil. This results in a product suitable for various applications, including food, cosmetics, and biofuels. Refined palm oil is also more resistant to rancidity, leading to a longer shelf life.

By-Products of Refining

The refining process generates by-products, including palm kernel cake, a valuable source of protein for animal feed. These by-products offer significant economic and environmental benefits, minimizing waste and maximizing resource utilization.

Fractionation of Palm Oil

Fractionation separates palm oil into different components based on their melting points and physical properties.

- Significance of Fractionation: Fractionation is crucial for producing specialized palm oil products with specific characteristics. Different fractions have distinct applications, including food, cosmetics, and industrial products.

Quality Control and Standards: Palm Oil Processing

Maintaining consistent quality is paramount in the palm oil industry, ensuring consumer safety and product reliability. Rigorous quality control procedures are essential to meet global standards, safeguard brand reputation, and comply with regulatory frameworks. This crucial aspect of palm oil processing goes beyond simple testing; it encompasses a comprehensive system that integrates testing methods, regulatory adherence, and certification processes.

Palm oil processing quality control is a multifaceted system that demands stringent adherence to standards and regulations, ensuring the safety and reliability of the final product. This involves a robust testing regimen, regulatory compliance, and certification procedures. Failure to meet these standards can result in significant financial penalties, reputational damage, and legal repercussions.

Importance of Quality Control

Quality control in palm oil processing is vital for safeguarding consumer health and maintaining market confidence. It ensures that the final product meets specific quality criteria, minimizing risks associated with impurities, contaminants, and adulteration. Consistent quality control procedures also facilitate fair trade practices and build trust with consumers.

Standards and Regulations

Palm oil processing is governed by a complex web of international and national standards and regulations. These regulations address various aspects of the process, from raw material sourcing to final product specifications. Examples include the requirements for pesticide residues, heavy metal content, and microbiological safety. These standards vary across regions and are often updated to reflect evolving scientific understanding and consumer expectations.

Methods for Testing and Analyzing Palm Oil Quality

A range of sophisticated analytical methods are used to assess the quality of palm oil. These methods include chemical analysis for determining fatty acid composition, moisture content, and the presence of contaminants. Physical tests, such as determining specific gravity and viscosity, can also provide critical information. Furthermore, sensory evaluation, often using trained panels, can assess color, odor, and flavor. Advanced techniques like chromatography are increasingly employed for precise identification and quantification of various components. These tests, combined with robust documentation and record-keeping, ensure traceability throughout the entire supply chain.

Ensuring Compliance with Quality Standards

Maintaining compliance with quality standards requires a proactive approach that integrates various measures. Regular internal audits and inspections are critical to identifying potential deviations and implementing corrective actions promptly. Employee training programs on quality control procedures are essential to ensure consistent adherence to standards across the entire production facility. Strict adherence to documented procedures, detailed record-keeping, and transparent communication are vital components of a robust quality management system.

Role of Certification Bodies

Certification bodies play a crucial role in verifying the adherence of palm oil processing facilities to established standards. Third-party certification, such as those issued by organizations like the Roundtable on Sustainable Palm Oil (RSPO), assures consumers and stakeholders that the processing facility is operating in a responsible and sustainable manner. These certifications are often required for access to global markets and represent a strong commitment to quality and ethical practices. The credibility and reputation of these bodies are directly correlated with the trust placed in the certified palm oil products.

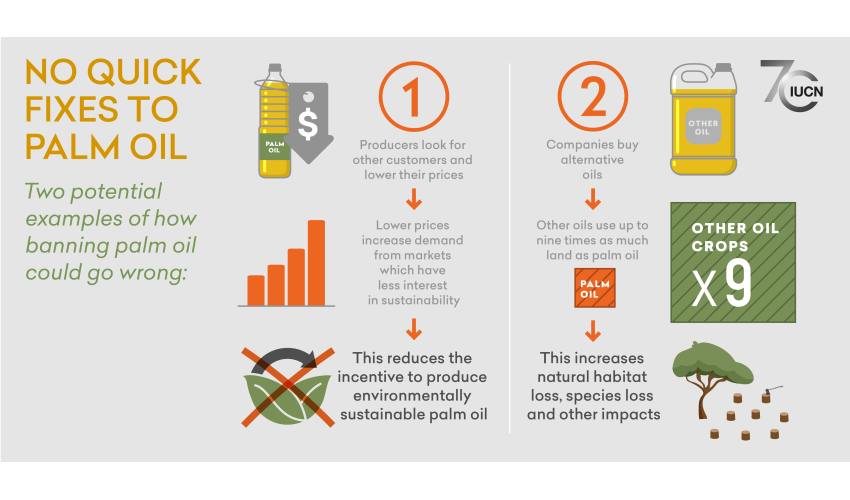

Environmental Considerations

Palm oil processing, a crucial component of the global agricultural economy, carries significant environmental ramifications. The industry’s expansion has sparked concerns regarding deforestation, biodiversity loss, and water pollution. Sustainable practices are crucial to mitigating these impacts and ensuring the long-term viability of palm oil production.

The environmental footprint of palm oil production hinges on a delicate balance between economic needs and ecological preservation. The industry’s success depends not only on efficient processing but also on environmentally responsible sourcing and cultivation methods. This necessitates careful consideration of land use changes, water management, and the preservation of surrounding ecosystems.

Environmental Impacts of Palm Oil Processing

Deforestation, a major concern, often occurs to make way for palm oil plantations. This leads to habitat loss for numerous species, impacting biodiversity and disrupting ecological balance. Furthermore, the large-scale conversion of natural ecosystems to palm oil plantations contributes to greenhouse gas emissions, accelerating climate change. The use of agrochemicals, including pesticides and fertilizers, can contaminate water sources, posing risks to human health and aquatic ecosystems. Wastewater discharge from processing plants can also lead to water pollution, affecting downstream communities and aquatic life.

Sustainable Palm Oil Processing Practices

Several initiatives aim to minimize the environmental damage associated with palm oil production. These include adopting sustainable land-use practices, reducing water consumption, and implementing effective wastewater treatment systems. The adoption of environmentally sound agricultural practices, such as reduced pesticide use and responsible fertilizer management, helps minimize pollution and protect surrounding ecosystems.

Potential Impacts on Biodiversity and Ecosystems

The conversion of natural habitats to palm oil plantations results in a loss of biodiversity, affecting numerous species, both plant and animal. This loss disrupts ecological processes and can have cascading effects on the entire ecosystem. The degradation of wetlands, forests, and other natural habitats due to palm oil expansion leads to the decline of local wildlife populations and the disruption of natural ecological balance. Furthermore, the fragmentation of habitats isolates populations, making them more vulnerable to threats such as disease and inbreeding.

Role of Responsible Sourcing in Minimizing Environmental Damage

Responsible sourcing plays a crucial role in mitigating the environmental impact of palm oil production. By supporting suppliers who adhere to strict environmental and social standards, consumers and businesses can encourage more sustainable practices throughout the supply chain. Certification schemes, such as the Roundtable on Sustainable Palm Oil (RSPO), provide a framework for verifying the environmental and social responsibility of palm oil producers. This transparency allows consumers to make informed decisions and support companies committed to sustainable practices.

Sustainable Palm Oil Processing Initiatives

| Initiative | Description | Benefits |

|---|---|---|

| Roundtable on Sustainable Palm Oil (RSPO) | A global certification scheme promoting sustainable palm oil production through a set of standards for environmental and social responsibility. | Ensures sustainable practices, reduces deforestation, protects biodiversity, and promotes responsible sourcing. |

| Forest Stewardship Council (FSC) | An international certification system for responsible forest management. | Supports sustainable forest management practices, helps prevent deforestation, and protects biodiversity. |

| No Deforestation, No Peat, No Exploitation (NDPE) | An initiative prohibiting deforestation, peatland conversion, and labor exploitation in palm oil production. | Promotes zero deforestation and ensures responsible labor practices, safeguarding biodiversity and ecosystems. |

Safety Procedures and Regulations

Palm oil processing, while vital for global markets, presents inherent safety risks. Robust safety protocols and regulations are crucial for minimizing these hazards and ensuring a safe working environment for personnel. Failure to adhere to these protocols can result in significant financial losses from downtime, injury compensation, and reputational damage.

A proactive approach to safety, encompassing comprehensive training, stringent regulations, and meticulous risk assessment at each processing stage, is paramount. This proactive stance fosters a culture of safety within the plant, leading to a healthier and more productive workforce.

Safety Protocols in Palm Oil Processing Plants

Effective safety protocols are foundational for mitigating risks in palm oil processing plants. These protocols encompass various measures, including stringent personal protective equipment (PPE) requirements, regular safety inspections, and emergency response plans. The implementation of these measures is vital for preventing accidents and injuries.

- Personal Protective Equipment (PPE): Mandatory use of appropriate PPE, such as safety glasses, gloves, and respirators, is essential at all stages of the processing. This safeguards workers from potential chemical splashes, airborne particles, and other hazards. For instance, specialized clothing designed to resist oil and heat should be provided to workers in the extraction and refining stages.

- Regular Safety Inspections: Routine inspections of machinery, equipment, and work areas are critical for identifying and addressing potential hazards. This proactive approach ensures the prompt rectification of any safety concerns, thereby preventing accidents. The frequency and scope of inspections should be tailored to the specific hazards presented by each stage of the process.

- Emergency Response Plans: Well-defined emergency response plans, including evacuation procedures and first aid protocols, are indispensable. These plans should be thoroughly communicated and practiced regularly to ensure a swift and coordinated response in case of emergencies. This includes having designated first aid stations and trained personnel readily available.

Potential Hazards and Risks

Palm oil processing presents a range of potential hazards across different stages. Understanding these hazards is crucial for implementing appropriate safety measures.

- Raw Material Handling: The handling of fresh palm fruit bunches can pose risks related to slips, trips, and falls due to the nature of the raw material and potentially hazardous substances. Properly designed handling equipment and safe work practices are vital.

- Oil Extraction Techniques: The high-temperature and high-pressure conditions in some extraction methods create hazards associated with burns, explosions, and equipment malfunctions. Specialized training for operating these machines and strict adherence to maintenance schedules are critical.

- Refining and Fractionation: The use of chemicals and solvents in refining and fractionation can present risks of chemical exposure and skin irritation. Appropriate ventilation systems and stringent handling procedures for chemicals are necessary.

Safety Measures and Guidelines

Implementing safety measures tailored to each stage of palm oil processing is critical. These measures should encompass hazard identification, risk assessment, and appropriate control measures.

- Hazard Identification and Risk Assessment: Systematic identification of potential hazards at each stage, followed by a comprehensive risk assessment, is a crucial step. This involves evaluating the likelihood and severity of each hazard to prioritize safety measures. Examples of this include establishing safety protocols for working with heavy machinery, and implementing systems to control the release of harmful substances.

- Control Measures: Implementing appropriate control measures, such as engineering controls, administrative controls, and personal protective equipment (PPE), is essential. This includes installing safety guards on machinery, implementing safety protocols for handling chemicals, and providing necessary training to employees.

- Training and Awareness Programs: Thorough training programs for all personnel are vital for instilling a safety-conscious culture. These programs should cover the specific hazards associated with each stage of the process, proper use of PPE, and emergency response procedures. Regular refresher courses are recommended to ensure ongoing awareness.

Regulations and Standards for a Safe Working Environment

Specific regulations and standards are crucial for maintaining a safe working environment in palm oil processing plants. Adherence to these regulations is vital to prevent accidents and protect workers’ health.

- National and International Standards: Complying with relevant national and international safety standards, such as those from OSHA (Occupational Safety and Health Administration) or ISO (International Organization for Standardization), is essential for establishing best practices and demonstrating commitment to worker safety.

- Compliance and Enforcement: Implementing a robust system for ensuring compliance with safety regulations and proactively addressing any non-compliance issues is crucial. Regular audits and inspections, combined with prompt corrective actions, can ensure adherence to standards.

Future Trends and Innovations

Palm oil processing is undergoing a period of significant transformation, driven by evolving consumer demands, environmental concerns, and technological advancements. The industry is embracing innovations to enhance efficiency, sustainability, and profitability, while simultaneously addressing the need for higher quality products. This necessitates a strategic approach to research and development to meet future challenges.

The push for sustainable practices is a defining characteristic of the modern palm oil industry. Innovations in processing methods aim to reduce environmental impact, while maintaining output and economic viability. This is achieved through a variety of approaches, from improved extraction techniques to more sustainable feedstock sourcing and waste management strategies. Furthermore, the integration of automation and digital technologies promises to optimize the entire processing chain.

Emerging Trends in Palm Oil Processing Technology

Several key trends are shaping the future of palm oil processing. These include the increased use of sustainable feedstocks, the adoption of advanced extraction techniques, and the implementation of stringent quality control measures. The demand for traceability and transparency throughout the supply chain is also rising, prompting the use of advanced technologies for tracking and monitoring.

New Technologies and Innovations

Innovative technologies are transforming palm oil processing. Supercritical fluid extraction, for instance, is gaining traction due to its potential for enhanced oil yield and reduced solvent usage compared to traditional methods. Membrane filtration technologies are also being explored for their capacity to improve oil quality and separation efficiency. Moreover, the application of nanotechnology is being researched for its potential to improve the efficiency of certain processing steps.

Automation and Digitalization in Palm Oil Processing

Automation is rapidly changing the landscape of palm oil processing. From automated harvesting and milling to robotic sorting and packaging, automation is improving efficiency and reducing labor costs. Real-time data analytics and process monitoring tools are also becoming crucial, providing insights into production parameters and facilitating proactive maintenance. This integration of digital technologies allows for more precise control over the entire process, optimizing yields and reducing waste.

Biotechnology in Palm Oil Processing

Biotechnology holds significant potential for advancing palm oil processing. Genetic engineering and other biotechnological tools could potentially enhance the quality and yield of palm fruit. Further research into microbial enzymes and other bio-based solutions may yield advancements in refining and fractionation, leading to more efficient and sustainable processes. This approach could yield significant improvements in oil quality and processing efficiency.

Research and Development in Improving Palm Oil Processing Methods

Continued research and development are crucial for improving palm oil processing methods. Research institutions and industry players are collaborating to explore innovative solutions, including sustainable feedstock options, more efficient extraction techniques, and advanced refining processes. This collaborative effort is critical to ensure that the palm oil industry remains competitive and sustainable in the long term. Examples include the development of bio-based solvents and the exploration of new enzymatic treatments for oil extraction. These advancements are critical to the industry’s long-term viability.

Palm oil processing, a crucial component of global food supply chains, often involves separating various components for diverse applications. Beyond its widespread use in food products, discover the health benefits of palm kernel oil for your skin and hair, Discover the Health Benefits of Palm Kernel Oil for Your Skin and Hair , highlighting its potential in personal care.

Further processing of these byproducts is key to maximizing the economic value of the palm oil industry.